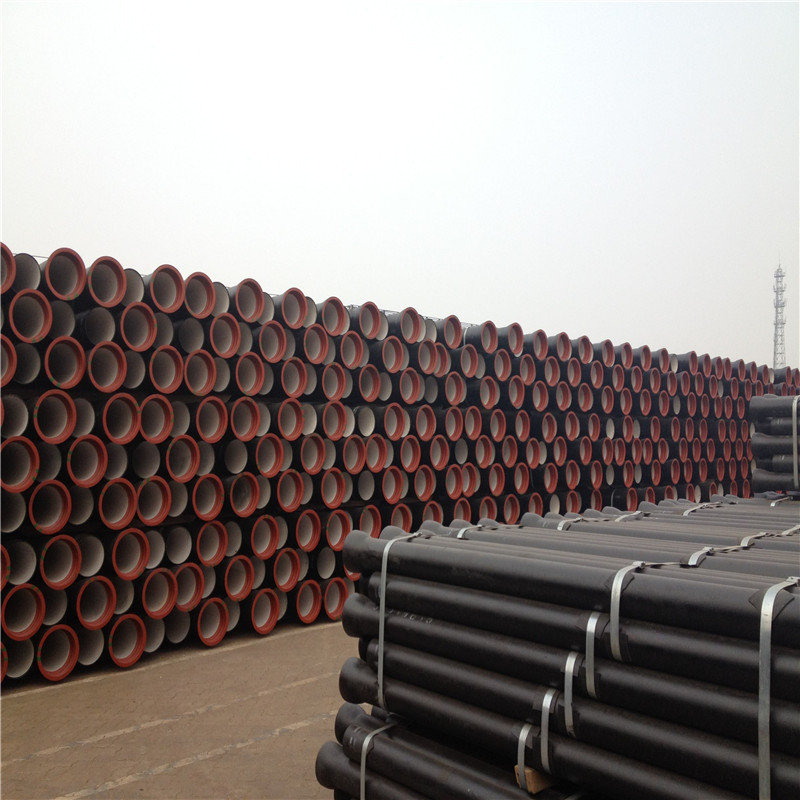

Factory and Warehouse

Product Form

Ductile Iron Pipes All Types:

|

1 |

Material |

Ductile Cast Iron |

|

2 |

Joint Type |

T-Type(push-on joint) |

| K-Type(Mechanical Joint) | ||

| Self-Restrained | ||

| Flanged joint | ||

|

3 |

Standard |

ISO2531, EN545, EN598, etc |

|

4 |

Size |

DN80 - DN2600 (80mm - 2600mm) |

|

5 |

Class |

K7 K8 K9 K12 C25 C30 C40 50 52 53 54 56 64 100 150 250 350 etc. |

|

6 |

Length |

6m, cut to 5.7m |

|

7 |

Internal lining

|

1. Portland cement mortar lining |

| 2. Sulphate Resistant cement mortar lining | ||

| 3. High-Aluminum cement mortar lining | ||

| 4. Epoxy Resin Lining | ||

| 5. Epoxy Ceramic Lining | ||

| 6. PU Lining | ||

|

8 |

External Coating |

Zinc+bitumen coating, |

| Customized coating such as Zinc-Epoxy, Alumina Powder, PU, FBE, Epoxy-Ceramic, etc. | ||

|

9 |

Rubber Gasket |

NBR rubber, SBR rubber or EPDM rubber ring as per ISO4633 |

|

10 |

Application |

Potable Water / Drinking Water/Sewage Water |

|

11 |

Packing |

DN100-DN300 in bundles; DN350-DN2600 in bulk ship |

Introduction

our Ductile Iron Pipes, available in a wide range of classes including Class 50, 52, 53, 54, 56, 150, 250, and 350, designed to meet diverse water conveyance needs. Crafted with precision from high-quality ductile iron, these pipes exemplify superior strength, toughness, and corrosion resistance.

Class 50 Ductile Iron Pipe is suitable for various applications, offering reliable performance under moderate pressure conditions.

Class 52 Ductile Iron Pipe is engineered to handle higher pressure demands, making it ideal for urban water mains and industrial settings.

Class 53 Ductile Iron Pipe is designed for robust performance under substantial pressure, well-suited for critical water transmission projects.

Class 54 Ductile Iron Pipe is a top choice for demanding water distribution systems, ensuring long-lasting efficiency.

Class 56 Ductile Iron Pipe provides exceptional strength and resilience for high-pressure applications in challenging environments.

Class 150, 250, and 350 Ductile Iron Pipes cater to specialized projects with varying pressure requirements, delivering unmatched durability and reliability.

All our Ductile Iron Pipes undergo rigorous testing, adhering to stringent industry standards to ensure unmatched quality and safety. Their versatility allows seamless integration into a wide range of projects, offering flexibility in size and pressure ratings.

Invest in our environmentally friendly Ductile Iron Pipes to experience long-lasting performance and cost-effectiveness in water conveyance solutions. Upgrade your infrastructure with our top-tier piping options, delivering efficiency and reliability at every turn. Choose Ductile Iron Pipe - Class 50, 52, 53, 54, 56, 150, 250, 350 - and elevate your water transportation systems to new heights.

Benefits of ductile iron pipe

Solid under loads

In underground conditions, the ductile cast iron pipe has a semi-rigid behaviour: it offers an excellent compromise between mechanical stress in the wall (small DN) and ovality (large DN). It can be laid in high and low height of cover, and easily in soil of low rigidity. The ”ground/semi-rigid pipe” system offers optimum mechanical stability over time, without risk of buckling in large DN.

Insensitive impacts

The ductile cast iron structure has a high elastic deformability and a high resistance to crack initiation: it results in excellent impact resistance. The cast iron pipes are perfectly suited to transport conditions over long distances (truck, train or ship), handling conditions on sites and to different types of backfilling. The ductile cast iron pipelines may be laid in very difficult areas: rocky mountain slopes for hydroelectric plants, crossings for cantilever bridges, rockfill for submarine outlets.

Push-in joint system

Excellent hydraulicity

The centrifugation process ensures a perfectly smooth and even cement surface. The Colebrook roughness coefficient of an isolated pipe is k = 0.03 mm. We recommend the use of an average value of k = 0.1 mm for sizing networks in order to take into account all the different load losses caused by singular points (tee fittings, elbows, valves, etc.)

Pressure resistance

The ductile cast iron pipe are designed to withstand pressures much greater than the values usually encountered on the networks. The wall thickness is calculated with a safety factor of 3 with respect to the maximum operating pressure. This additional safety margin is very useful to the impacts during installation, accidental overpressure and mechanical operating fatigue.